Brief Introduction

Micro powder grinding mil is designed by our R&D department on the basis of multiple innovation and tasting. it has beenprovgd by thousands of customers that our machine has outstanding features, stable qually, easy operation and maintenance.It is the ideal equipment for fine powder milling.

Scope

HGM Serles Mlcro Powdar Grinding Ml ls the equlpment speclallzing In producing fine and superine powdar of non-infammable.non-axploslve and brite materials with Moh’s hardnesg under sl, such as calcite, chalk, llmestone, dolomite, kaolin, bentonite,talc, mlca, magneslte, llte, pyrophyllte and vermlcullte, seplollte, atapulglte, recorte, dlatomite, barte, gypsum, alunite,graphlte, fuorte, rockphosphate, Kallum ore, pumice, fy ash, etc., totally more than 100 kinds of materlals.

Working Principle

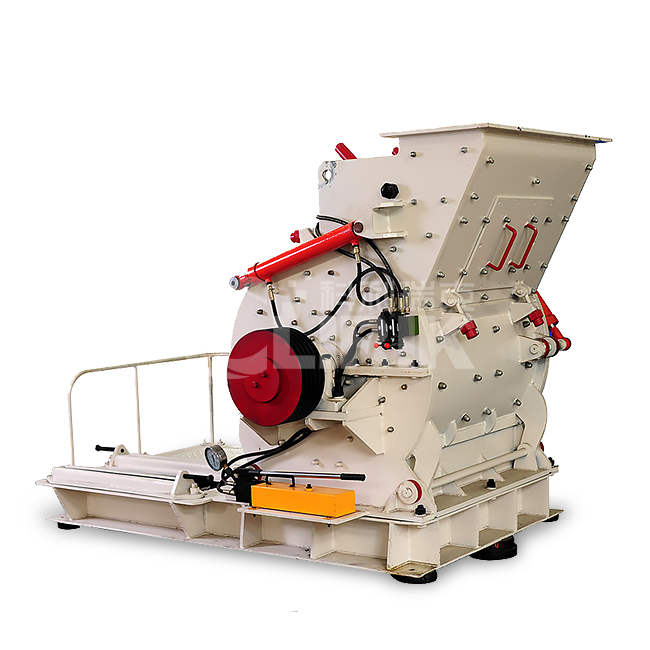

HGM series micro powder grinding mill mainly consist of main unit, classifer, powder colector, dust cleaner, blower, muflersound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After crushed by hammer crusher, the large materals become small ones and are sent to storage hopper by elevator, and thenevenly sent to the upper distribution plate of the tum plate by vlbrating feeder and sloping feading plpe.

When the grinding millis at work, the main bearing and each dial are driven by elecdromotor of main equipment through reducerand all the grinding rollers are roling in the ring channels driving by dial through plunger. The materials are driven to the edge othe tur plate by the certrifugal force and fall down into the grinding chambers where the materials are repeatedly pressedcrushed and grinded by the rollers. Then the materials fal into muliple layers and to be crushed and ground continuously to micrcpowder.

The high-pressure alr biower constanty inhales alr within the grinding mll and, in tum, the airiow with crushed materals arebrought to the classifler whose high-speed impeller will screan the alrilow: the unquallled particle size wll fall and retum to themll for belng reground whlle the quallled particle slze mlxed with alr wll go Into the cyclone powder collector. Most of the qualllecpowders wl fall and exit from the diacharging valve at the bottom; a small proportion of the fine powders, with alrlow, moves fcthe dust cleaner, and clings to the surace of the flter bags. At the same time, the fine powders clinging to the surface fall dowrby the sudden vibratlon of the filtar bags, which ls caused by the instanty elecied high-pressure gas controled by the pulse valveThe materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. in additlon, fiteredclean alr will be emitted from the alr outlet of mufler in the end.

Features

High Efciency

Under the same finished final size and the same motor power, the capacity of micro powder grinding milis twice as much as jetrnill, mnixding grinder and ball mill, and energy consumption decreased 30%.

Long llecycle of spare parts

The ring and roler are forged by speclal materal wth high utlization. Under the same grinding materlal and finish speclal aize, thelfecycle of spare parts is about one year, which ls 2-3 times longer than lmpact mll or furbo mll. Furtherore, the lfetime canreach 2.5 years for grinding calclte carbonate.The lfecycle of spare parts ls varlable for the materlal’s hardness.

High safety and reliability

As no roling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings andseal components.High finenees, fiexdble adjustnent

The final finenass of the grinding materials can be adjusted between 200 mashes and 2500 mesh (74-5 micron).

Envronment-friendly

The application of pulse bag fiter and muffer greatly alleviates dust pollution and noise.

Advanced intelligent speed control devica

Let the material feed into the machine avenly,adjust the main speed to fit for grinded material,the fineness more stable. So as toincrease the capacity and afciency, reduce the power consumption.

Parameter

Note: The capaclty ls based on the domestlc CaCO, Powder factory’s feedback.

Note: For the data with prefix such as “2*xx”, which means there are two same motors configured for one itam.