Overview

CLQM Series Airflow Vortex Mill (jet mill) is one of today’s most widely used grinding machines for reducing dry fine chemicals, food products, and other materials.

It combines a mechanical impact mill with a dynamic air classifier for middle-small volume continuous processing.

After several years of experience, it can be customized to different materials.

The mill can be equipped with varying grinding tracks and other impact elements, depending on the product and final product specs.

CLQM Airflow Vortex Mill Application

With over 1000 references worldwide, it is used the most industry:

1. Chemicals: Bisphenol, tartaric acid, E-PVC, fungicides, herbicides, stearates.

2. Powder coatings: Epoxy, polyester, hybrids, UV-curing acrylates, polyamide.

3. Food: Sugar, cacao, starch, fish meal, xanthan, guar flour, lactose.

4. Pharma/cosmetics: Face powder, ascorbic acid, tartaric acid.

5. Minerals: Talc, kaolin, calcium sulphate, bauxite, limestone.

Working Principle of Airflow Vortex Mill

Main Structures

CLQM series airflow vortex mill mainly consists of the screw feeder, grinding unit, classifier, power section, cyclone, filter, blower, electrical panel etc.

The main motor, mill disc, mill blocks, classifier, inlet liner, main shaft, mill baffle.

Main Unit Components:

1. Unit base

2. Lower body

3. Main bearing assembly

4. Middle body

5. Fixed blocks

6. Mill disc

7. Airflow baffle

8. Classifier impeller

9. Upper cover

10. Outlet hole

11. Classifier bearing assembly

12. Hopper

13. Feeding part

Working Principle

The material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating grinding disc.

At the same time, it is subjected to centrifugal force and collides with the grinding ring gear, and is subjected to various comprehensive forces such as shearing, friction and collision to finished grinding.

The grinded material moves to the classifying zone with the airflow.

The classifier is adjusted by frequency conversion, separates the coarse and fine materials, the product that meet the fineness requirement enters the cyclone collector and the dust collector with the airflow, and the coarse powders return to the classifying zone, secondary grinding.

The Main Spare Parts of Airflow Vortex Mill

Benefit

- 1. Muti-function combination: cooling, drying, grinding and classifying.

- 2. Different types of grinding disc (pin, hammer, teeth or others) are used based on characteristics of materials to obtain different grinding forces and improve grinding efficiency.

- 3. Key parts like the hammer, gear ring and classifying wheel are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product.

- 4. Compact structure and small occupation, easy to disassemble and clean.

The different characters in the various mills:

The influence of airflow volume and classifier wheel speed on particle size:

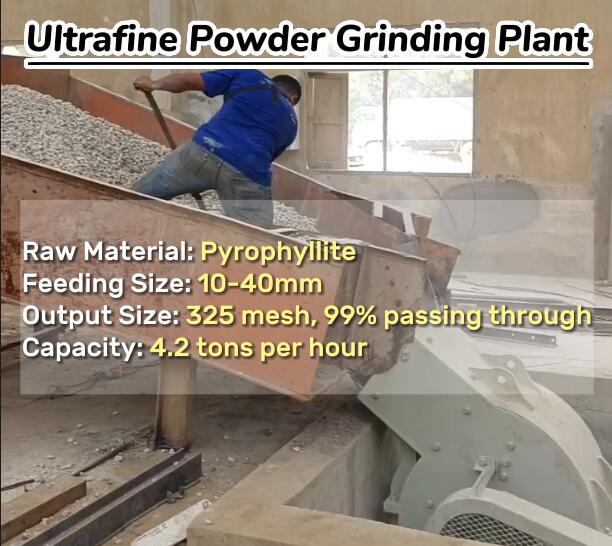

Customer Sites:

Specifications

Parameter 1

Model | Motor(kw) | Rotated Speed(rpm) | ||||

| Main Unit | Classifier | Feeder | Main Unit | Classifier | Feeder | |

| CLQM-15 | 7.5 | 0.75 | 0.55 | 7000 | 800-3000 | 20-100 |

| CLQM-20 | 11 | 1.1 | 0.55 | 5500 | 750-3100 | 20-100 |

| CLQM-30 | 22 | 4 | 0.55 | 4000 | 700-2800 | 20-100 |

| CLQM-45 | 30 | 5.5 | 0.55 | 3500 | 650-2600 | 20-100 |

| CLQM-60 | 45 | 7.5 | 0.55 | 3000 | 600-2400 | 20-100 |

| CLQM-100 | 55-75 | 11 | 1.1 | 2000 | 500-2000 | 20-100 |

| CLQM-125 | 90-110 | 15 | 1.1 | 1600 | 400-1600 | 20-100 |

Parameter 2

| Model | Diameter of rotor disc (mm) | Diameter of gear ring (mm) | Diameter of classifier (mm) | Linear speed of the outermost end of the rotor disc (m/s) | Air volume (m³/h)(max) | Product fineness (μm) | Output (kg/h) | Main Unit Dimension (L*W*H mm) |

| CLQM-15 | 300 | 366 | 175 | 110 | 700-1200 | 3-300 | 10-200 | 1450*900*1000 |

| CLQM-20 | 300 | 366 | 175 | 87 | 1300-2800 | 5-300 | 20-600 | 1450*900*1000 |

| CLQM-30 | 400 | 470 | 242 | 84 | 2200-3600 | 5-300 | 30-1000 | 1740*1190*1100 |

| CLQM-45 | 550 | 601 | 274 | 102 | 3600-6500 | 10-300 | 40-1200 | 1940*1250*1170 |

| CLQM-60 | 700 | 774 | 350 | 110 | 4000-7500 | 10-300 | 50-1500 | 2150*1460*1380 |

| CLQM-100 | 1000 | 1080 | 414 | 106 | 8000-12000 | 10-300 | 80-3000 | 2840*2150*1760 |

| CLQM-125 | 2000 | 1295 | 461 | 101 | 12000-16000 | 10-300 | 120-5000 | 3000*2380*2000 |