CLIRIK Machinery’s HGM ultrafine grinding mill is typically suitable for processing eggshell powder within a fineness range of 5 to 74 microns (200-2500 mesh).

The process of using HGM ultrafine grinding mills to turn eggshells into valuable resources involves the following steps:

1. Preliminary Treatment of Eggshells

►Cleaning: The collected eggshells need to be thoroughly cleaned to remove any remaining egg whites, yolks, and other impurities.

►Drying: After cleaning, the eggshells should be air-dried or dried using drying equipment to ensure they are completely dry inside and out, making them ready for further crushing.

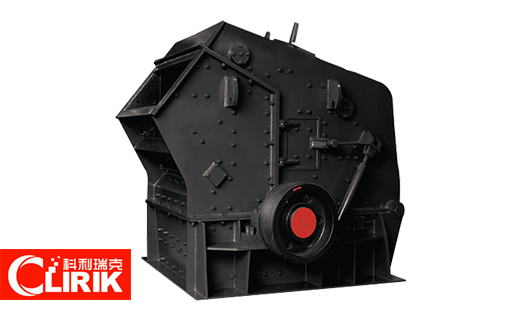

2. Coarse Crushing of Eggshells

►Initial Crushing: Crush dried eggshells into particles (<20mm) using coarse crushing equipment or a general crusher to facilitate subsequent ultrafine grinding.

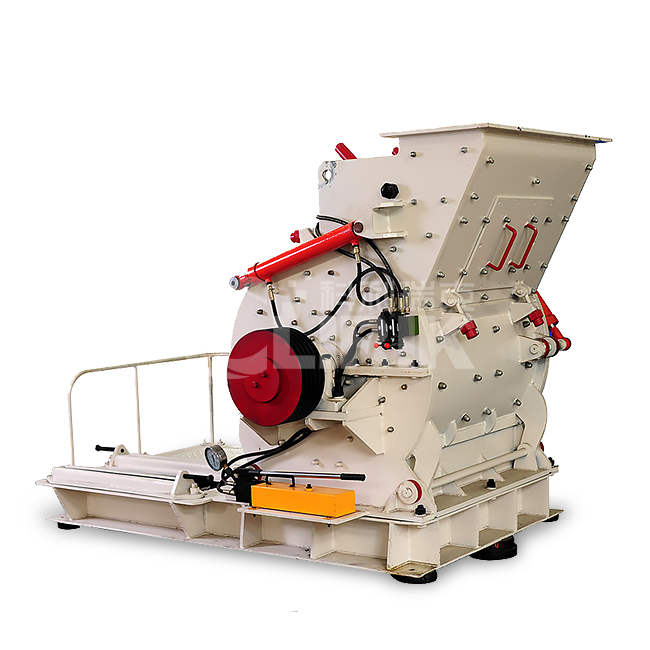

3. Ultrafine Grinding with HGM Mills

►Feeding: The coarsely crushed eggshell particles are fed into the HGM ultrafine grinding mill through a feeding device.

►Ultrafine Grinding: Inside the HGM mill, the eggshell particles are repeatedly ground and crushed between the grinding rollers and rings, ultimately achieving ultrafine particles at the micron or nanometer scale.

►Classification and Collection: The mill’s classifier auto-separates qualified powder, recycles unqualified particles for regrinding, and collects final product in a dedicated system.

HGM Ultrafine Grinding Mill for Eggshells Powder Making

4. Applications of Ultrafine Eggshell Powder

►Agricultural Use: Ultrafine eggshell powder can be used as an efficient calcium fertilizer, directly applied to the soil to increase calcium content and promote crop growth.

►Food Additives: After further processing and testing, the ultrafine eggshell powder can be used in the food industry as a calcium supplement added to various foods.

►Pharmaceutical Field: The ultrafine eggshell powder can also be used in pharmaceuticals as a calcium supplement or as a carrier for other drug ingredients.

5. Quality Control and Packaging

Quality Testing: Powder is tested for purity, particle size, and compliance before packaging.

Packaging: Packaged for specific applications, with proper storage/transport.

Value Creation: HGM mill transforms eggshells into high-value additives, enabling resource recycling and eco-benefits.

How does it cost?

The cost of using an HGM ultrafine grinding mill to process eggshells can vary depending on several factors:

1. Equipment Costs

HGM Ultrafine Grinding Mill: The price of an HGM ultrafine grinding mill can range from $20,000 to $200,000 or more, depending on the model, capacity, and features.

Supporting Equipment: Additional costs might include feeders, classifiers, dust collectors, and packaging machines, which can add another $10,000 to $50,000.

2. Operational Costs

Energy Consumption: The power consumption of an HGM ultrafine mill varies depending on its capacity, typically ranging from 30 to 150 kWh. The cost of electricity will depend on local rates.

Maintenance: Regular maintenance, including wear parts replacement (such as grinding rollers and rings), can add to the operational costs.

Labor: Operating the mill requires skilled labor, and labor costs will vary based on local wages.

3. Raw Material Costs

Eggshell Collection: Sourcing eggshells externally (e.g., food processors) incurs raw material costs, which may be minimal when recycling waste.

Pre-processing Costs: Cleaning, drying, and initial crushing of eggshells might involve additional labor and energy costs.

4. Processing Scale

Small-Scale Production: If you’re processing a small volume of eggshells, the overall costs will be lower, but the cost per unit of processed material will be higher.

Large-Scale Production: Scaling up production can reduce the cost per unit, but initial capital investments will be higher.

5. Location and Logistics

Transportation Costs: Moving raw eggshells to the processing facility and transporting finished products to customers can also impact costs.

Regulatory Compliance: Depending on your location, there may be costs associated with meeting environmental regulations, waste disposal, and other legal requirements.

6. Product Value

Market Price of Processed Eggshell Powder: The revenue generated from selling ultrafine eggshell powder will depend on the market demand and pricing, which varies by application (e.g., agricultural, food, pharmaceutical).

Overall Estimate:

Initial setup costs range from 50kto-300k+, with variable operational costs by production scale. Profitability hinges on pricing eggshell powder to cover costs and ensure margins.