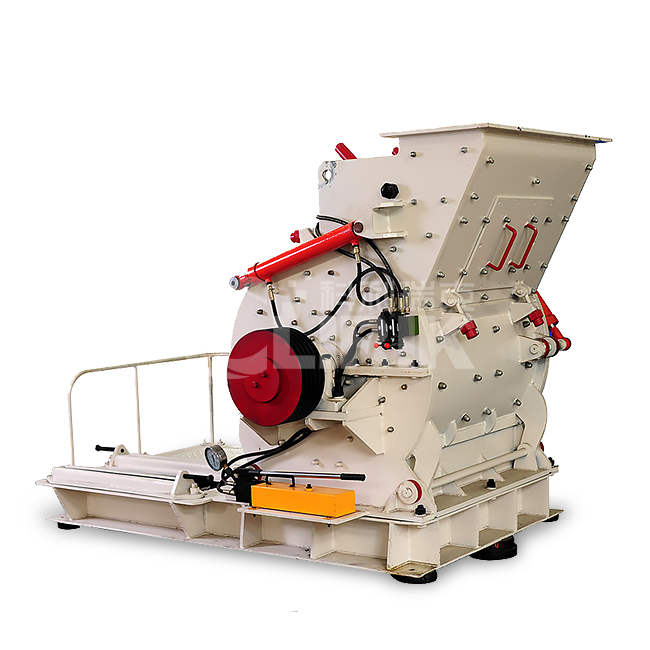

HGM100 Dual-P Ring Roller Mill for India: 10-Micron Calcium Carbonate Precision Processing Line Loaded and Shipped

The HGM100 Dual-P Ring Roller Mill employs a dual-power drive system and multi-stage grinding technology, breaking through the efficiency limitations of traditional ring roller mills to achieve precise control of calcium carbonate powder with D97 ≤10μm.

Its intelligent classification and low-temperature systems prevent over-grinding, maintaining ≥95° whiteness for premium fillers in coatings and plastics.

Process Advantages

30% lower energy consumption per ton vs. Raymond/vertical mills, thanks to laminated crushing. IoT-driven remote monitoring auto-adjusts mill load and classification, boosting product qualification to 99.2%.

Modular design enables flexible 325-2500 mesh production for water-based coatings and anticorrosive paints.

Global Implementation

As a flagship product of China’s high-end grinding equipment, the HGM100 Dual-P has served over 180 countries worldwide. Recently, multiple units were shipped to India and successfully applied in large-scale calcium carbonate projects, demonstrating a 40% increase in production capacity and dust emissions surpassing international standards.

Its full-process digital management system and EPCO service model (Engineering, Procurement, Construction, and Operations,ISO certification) ensure rapid response to customized requirements, driving innovation in non-metallic mineral deep-processing industries.