Overview

A stone crushing plant is a facility designed to crush various materials, such as rocks, garbage, or building materials.

It serves as a complete solution for crushing tasks and can be stationary or mobile.

Stone crushing plants can vary in size and complexity depending on the desired output and the type of stones being processed.

Crusher may include primary, secondary, and tertiary crushers, as well as conveyors, screens, and other equipment to facilitate the crushing and screening process.

Stone Crushing Plant Production Process

In a stone crushing plant, various devices and equipment are used to process the raw materials efficiently, such as stone crushers, screening equipment, conveyors, storage bins and hoppers etc.

- 1. Primary crusher: This is the initial crusher used to break down large stones into smaller pieces. Jaw crushers, hammer crushers, or impact crushers are commonly used as primary crushers.

- 2. Secondary crusher: After the primary crushing stage, secondary crushers are used to further reduce the size of the stones. Cone crushers, impact crushers, or vertical shaft impactors (VSI) are commonly used for secondary crushing.

- 3. Tertiary crusher: Some stone crushing plants may include a tertiary crusher to produce finer-sized materials. Tertiary crushers can further reduce the size of the crushed stones and produce cubical-shaped particles. Cone crushers and vertical shaft impactors are often used as tertiary crushers.

- 4. Screening equipment: Screens are used to separate the crushed stones into different sizes based on their particle size. Vibrating screens or trommel screens can be used for this purpose.

- 5. Conveyors: Conveyors are used to transport the raw materials between different stages of the crushing process. They ensure the smooth flow of materials and help optimize the efficiency of the plant.

- 6. Storage bins and hoppers: These are used to store the raw materials before they are fed into the crushers. Proper storage ensures a steady supply of materials to the crushing equipment.

- 7. Dust suppression systems: To control dust emissions generated during the crushing process, dust suppression systems such as water sprayers or fog cannons may be installed.

- 8. Washing equipment: In some cases, stone materials may need to be washed to remove impurities such as clay, silt, or dust. Washing equipment such as sand screws or log washers can be used for this purpose.

- 9. Control systems: Modern stone crushing plants often feature advanced control systems to monitor and optimize the operation of the equipment, ensuring efficient production and minimizing downtime.

These are some of the essential devices and equipment commonly used in stone crushing plants. The specific equipment required may vary depending on factors such as the type of stones being processed, the desired output size, and the production capacity of the plant.

Stone Crushers

Jaw Crushers:

Description: Jaw crushers are primary crushers designed to break down large stones into smaller pieces by applying compressive force.

Working Principle: A fixed jaw and a movable jaw form a V-shaped chamber. The movable jaw exerts force on the rock by pressing it against the fixed jaw, causing it to break.

Advantages:

1. Simple structure and easy maintenance.

2. High crushing ratio, producing uniform-sized particles.

3. Suitable for various materials, including hard and abrasive ones.

Disadvantages:

1. Limited capacity compared to some other types of crushers.

2. May generate more dust compared to other crushing methods.

Applications: Widely used in mining, quarrying, recycling, and construction industries for primary crushing of various materials.

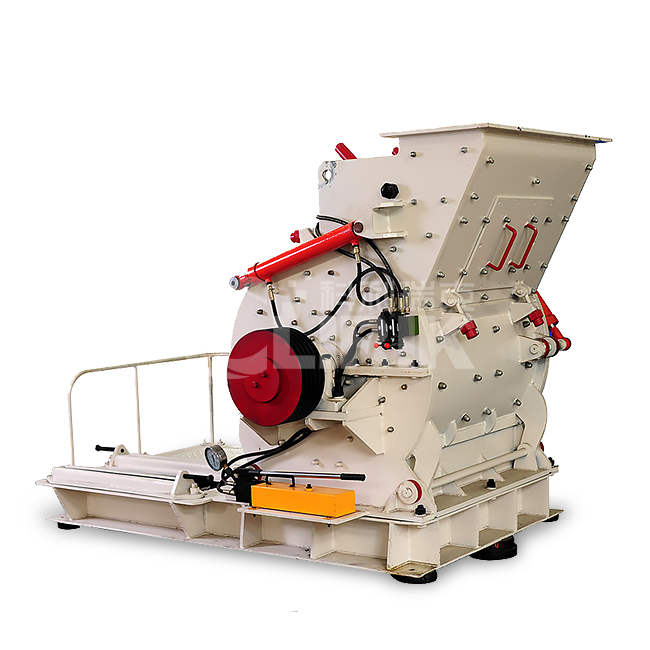

Hammer Crushers:

Description: Hammer crushers, also known as hammer mills, use high-speed rotating hammers to impact and break down materials.

Working Principle: Material is fed into the hammer mill chamber and struck by the rotating hammers. The impact of the hammers against the material causes it to fracture into smaller pieces.

Advantages:

1. Simple structure and easy maintenance.

2. Can handle a wide range of materials, including soft to hard and brittle materials.

3. High reduction ratio.

Disadvantages:

1. Prone to wear and require regular maintenance.

2. Not suitable for materials with high moisture content.

May produce more fines compared to some other crushers.

Applications: Hammer crushers are commonly used for crushing coal, limestone, gypsum, and other materials in industries such as mining, cement, and metallurgy.

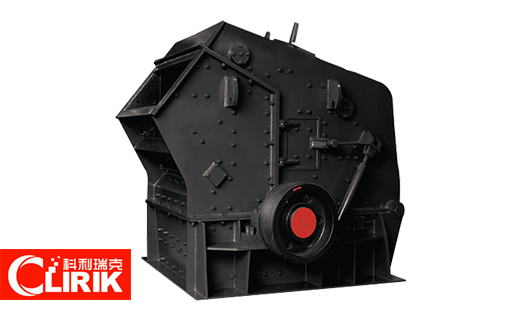

Impact Crushers:

Description: Impact crushers use impact force to crush materials, typically using a rotating rotor with hammers or blow bars.

Working Principle: Material is fed into the chamber and struck by the rotating rotor or bars, causing it to break into smaller pieces upon impact.

Advantages:

1. Versatile and suitable for various applications due to adjustable impactor settings.

2. High reduction ratio, producing cubic-shaped particles.

3. Can handle materials with high moisture content.

Disadvantages:

1. Higher wear and maintenance costs compared to some other crushers.

2. Less suitable for abrasive materials or materials with high silica content.

Applications: Used for primary, secondary, or tertiary crushing in quarrying, mining, recycling, and construction applications. Commonly used for producing aggregates for concrete and asphalt production.

Cone Crushers:

Description: Cone crushers operate similarly to gyratory crushers but have a different crushing chamber design. The cone-shaped crushing chamber is formed by a concave and a mantle, with the mantle rotating eccentrically within the concave.

Working Principle: Material is fed into the top of the cone crusher and is crushed between the mantle and the concave. The eccentric motion of the mantle causes the rock to be crushed against the concave.

Advantages:

1. High reduction ratio and efficient operation.

2. Uniform particle size distribution.

3. Suitable for medium to hard and abrasive materials.

Disadvantages:

1. Higher initial investment compared to some other types of crushers.

2. Maintenance and replacement of wear parts can be costly.

3. Not as effective for handling sticky materials.

Applications: Cone crushers are commonly used in secondary and tertiary crushing stages in mining, quarrying, and aggregate production applications.

Vertical Shaft Impactors (VSI):

Description: Vertical shaft impactors (VSI) crushers use a high-speed rotor with wear-resistant tips to crush material through impact.

Working Principle: Material is fed into the center of the rotor, where it is accelerated to high speed and then ejected against the stationary anvils or rock lining in the crushing chamber, causing fracturing and shaping of the material.

Advantages:

1. Produces cubical-shaped particles.

2. Versatile and can be used for shaping as well as crushing.

3. Low operating cost per ton.

Disadvantages:

1. Sensitive to feed gradation and moisture content.

2. High wear costs for rotor and wear parts.

3. May require frequent adjustment of operating parameters.

Applications: VSI crushers are widely used for producing high-quality aggregates for asphalt and concrete production, as well as for shaping fine particles in the mining and construction industries.

Benefit

Welcome to contact us to get a complete solution!

1. Tailored Solutions for Cost Reduction and Efficiency Improvement:

Clirik Machinery offers customized gravel production lines tailored to customer needs. These solutions are designed to be simple and efficient, requiring fewer pieces of equipment and ensuring smooth operation, ultimately reducing operating costs.

2. Excellent Product Quality with Good Shape and Gradation:

Our gravel production lines utilize a multi-stage crushing process, resulting in high-quality finished products with excellent particle shape and gradation, meeting the demand for premium materials.

3. Environmentally Friendly and Safe Operations:

Safety is paramount in our projects. We ensure stable and reliable ladder positions and guardrails, surpassing national electrical safety standards.

4. Long-lasting Wear-resistant Parts and Enhanced Production Efficiency:

By employing energy-efficient motors and high-performance equipment, our gravel production lines achieve exceptional production efficiency. Adopting full thin oil lubrication simplifies equipment maintenance and reduces labor costs. Additionally, high-quality wear-resistant parts minimize equipment wear, lowering production and operation expenses.

5. High-Quality Aggregates Generating Added Value:

Our professional team provides core equipment and solutions, ensuring reliable equipment quality and seamless process flow. This not only meets customer standards but also yields significant returns on investment.

Specifications

1. Jaw Crusher

| Type | Opening Size(mm) | Max. Feed Size(mm) | Output Open Range(mm) | Power(KW) | Capacity(t/h) | Size(mm) | Weight(t) |

| Pex-150*250 | 150*250 | 125 | 10-40 | 5.5 | 1-5 | 875*758*850 | 0.81 |

| Pex-150*750 | 150*750 | 125 | 18-48 | 15 | 5-16 | 1200*1500*1200 | 3.8 |

| Pex-250*750 | 250*750 | 210 | 25-60 | 22-30 | 16-30 | 1667*1545*1020 | 5 |

| Pex-250*1000 | 250*1000 | 210 | 25-60 | 30-37 | 16-50 | 1530*1992*1380 | 7 |

| Pex-250*1200 | 250*1200 | 210 | 25-60 | 37 | 20-60 | 1900*2192*1430 | 8 |

| Pex-300*1300 | 300*1300 | 250 | 25-105 | 75 | 20-90 | 2720*1950*1600 | 11 |

2. Hammer Crusher

| Type | PCC4008-75 | PCC40012-90 | PCC40015-132 |

| Rotor Diameter/mm | 750 | 900 | 1150 |

| Rotor Width/mm | 800 | 1200 | 1500 |

| Rotor Speed r/min | 800-1000 | 800-1000 | 550-800 |

| Feed head size/mm | 320*930 | 400*1200 | 500*1500 |

| Feeding Size/mm | ≤50 | ≤60 | ≤80 |

| Finished Size/mm | ≤3 | ≤3 | ≤8 |

| Capacity t/h | 10–30 | 30–60 | 50–100 |

| Powder/kw | 55-75 | 75-90 | 110-132 |

| Hammer Number (piece) | 18 | 32 | 32 |

| Overall Size L*W*H/mm | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |

3. Impact Crusher

| Model | Rotor Size*length (mm) | Feed Opening Size (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 35-50 | 55 | 2400×1558×2660 |

| PF1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 4-75 | 2455×2086×2800 |

| PF1210 | Φ1250×1050 | 400×1080 | 350 | 60-120 | 6-110 | 2590×2050×2800 |

| PF1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | 6-132 | 2590×2400×2810 |

| PF1315 | Φ1300×1500 | 860×1520 | 350 | 120-260 | 6-200 | 2930×2760×3050 |

| PF-1515 | Φ1500×1500 | 1145×1520 | ≤500 | 220-280 | 280kw | 2690×2049×2698 |

| PF-1520 | Φ1520×2000 | 1245×2050 | 700 | 300-550 | 315-440 | 3581×3560×3865 |

4. Cone Crusher

| Model | Cavity Size (Coarse/Fine) | Minimum Discharging Size (mm) | Max Feeding Size (mm) | Capacity (t/h) | Power (kw) |

| HPT100 | C1 | 140 | 19 | 50-140 | 90 |

| C2 | 100 | 13 | 50-140 | 90 | |

| M | 70 | 9 | 50-140 | 90 | |

| F1 | 50 | 9 | 50-140 | 90 | |

| F2 | 20 | 6 | 50-140 | 90 | |

| HPT200 | C2 | 185 | 19 | 90-250 | 160 |

| M | 125 | 16 | 90-250 | 160 | |

| F1 | 95 | 13 | 90-250 | 160 | |

| F2 | 75 | 10 | 90-250 | 160 | |

| HPT300 | C1 | 230 | 25 | 110-440 | 250 |

| C2 | 210 | 19 | 110-440 | 250 | |

| M | 150 | 16 | 110-440 | 250 | |

| F1 | 105 | 13 | 110-440 | 250 | |

| F2 | 80 | 10 | 110-440 | 250 | |

| HPT400 | C1 | 295 | 30 | 135-630 | 315 |

| C2 | 251 | 25 | 135-631 | 315 | |

| M | 196 | 20 | 135-632 | 315 | |

| F1 | 110 | 13 | 135-633 | 315 | |

| F2 | 90 | 10 | 135-634 | 315 | |

| HPT500 | C1 | 330 | 38 | 220-790 | 400 |

| C2 | 290 | 30 | 220-790 | 400 | |

| M | 210 | 22 | 220-790 | 400 | |

| F1 | 135 | 16 | 220-790 | 400 | |

| F2 | 95 | 13 | 220-790 | 400 | |

| HPT800 | C1 | 350 | 38 | 310-1200 | 630 |

| C2 | 299 | 32 | 310-1200 | 630 | |

| M | 265 | 25 | 310-1200 | 630 | |

| F1 | 220 | 16 | 310-1200 | 630 | |

| F2 | 150 | 13 | 310-1200 | 630 |