Brief Introduction

Our R&D team’s innovative Micro Powder Grinding Mill delivers excellent performance, stable quality, and easy operation. Proven by thousands, it’s the ideal choice for fine powder milling.

Scope

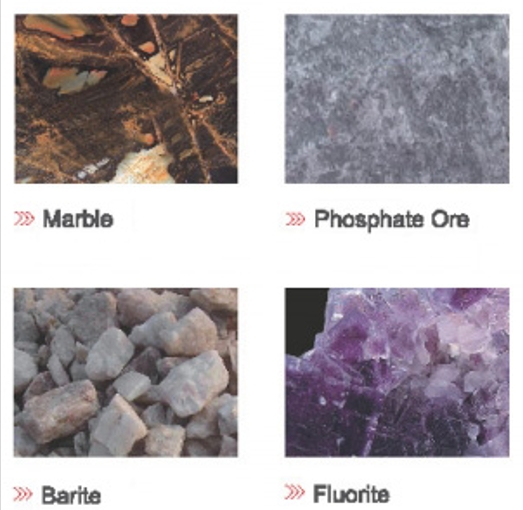

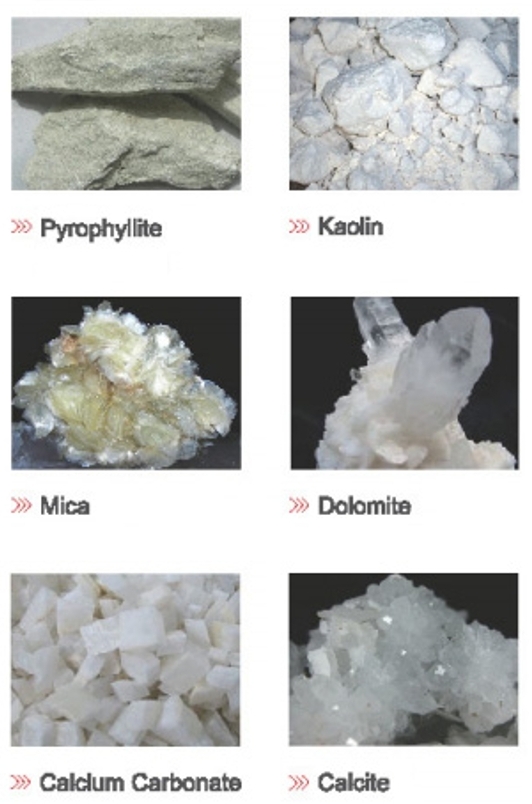

The HGM Series Micro Powder Grinding Mill specializes in producing fine and superfine powder of non-flammable, non-explosive, and brittle materials with Moh’s hardness under 6.

It processes over 100 materials, including calcite, limestone, kaolin, talc, gypsum, graphite, and more.

Working Principle

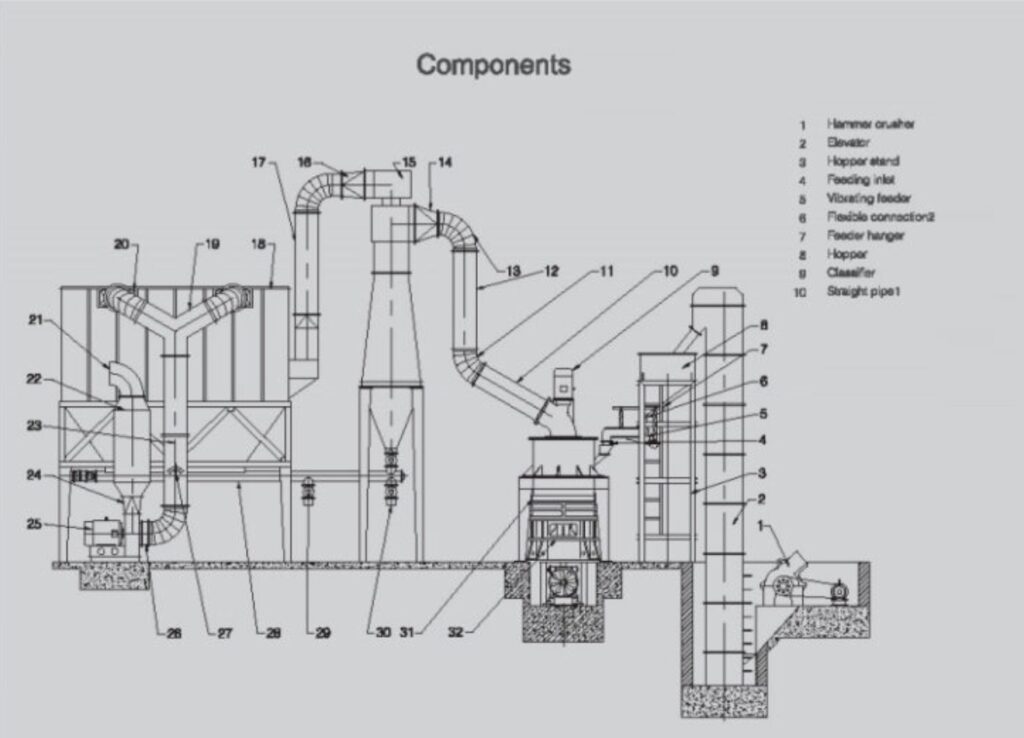

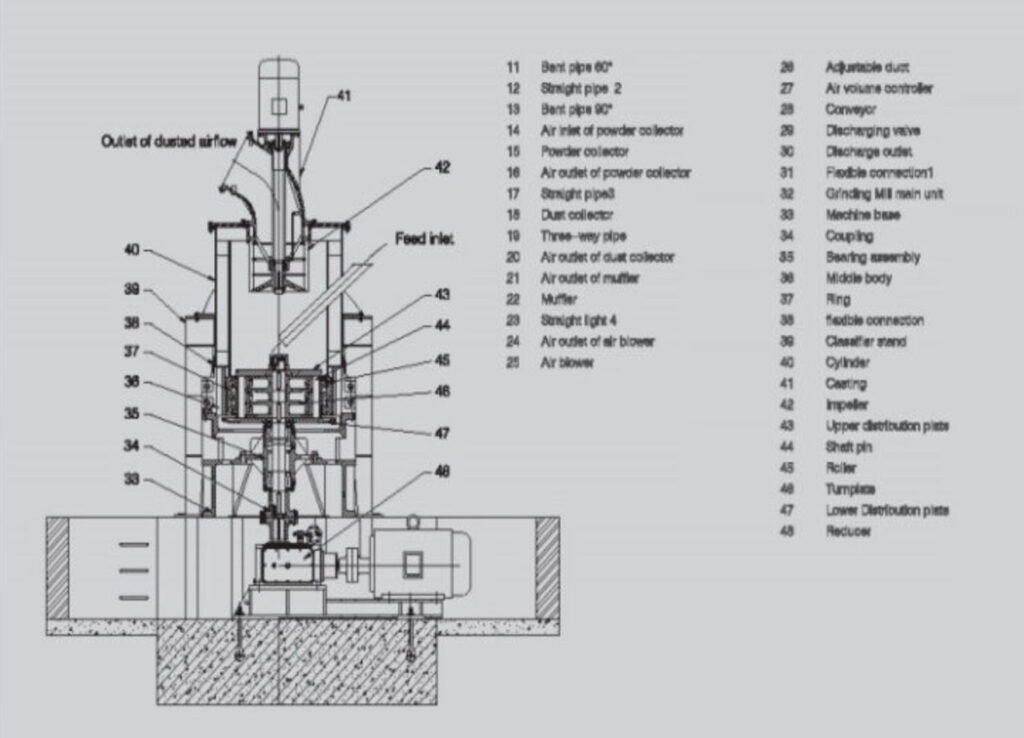

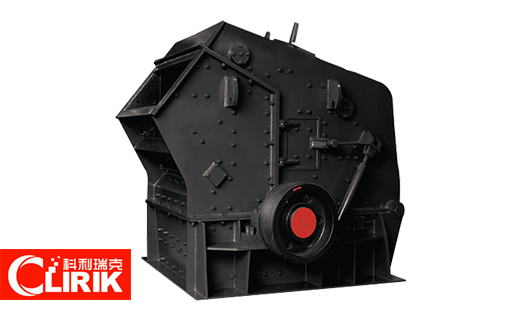

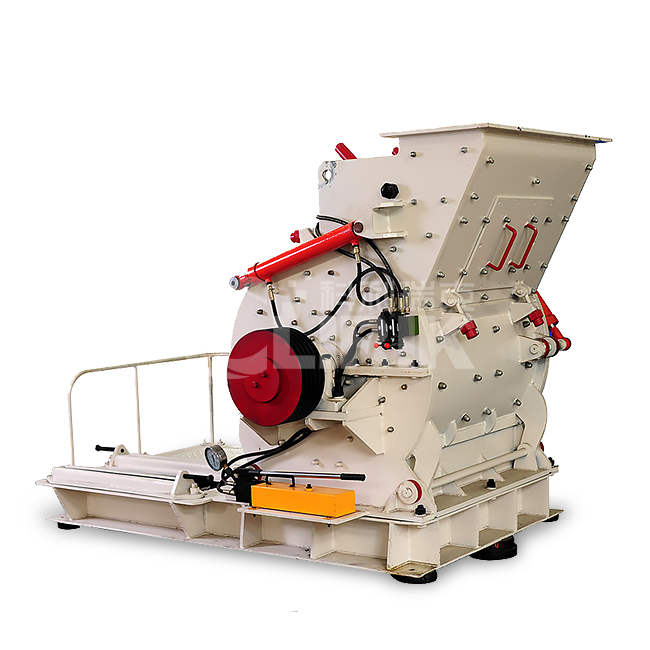

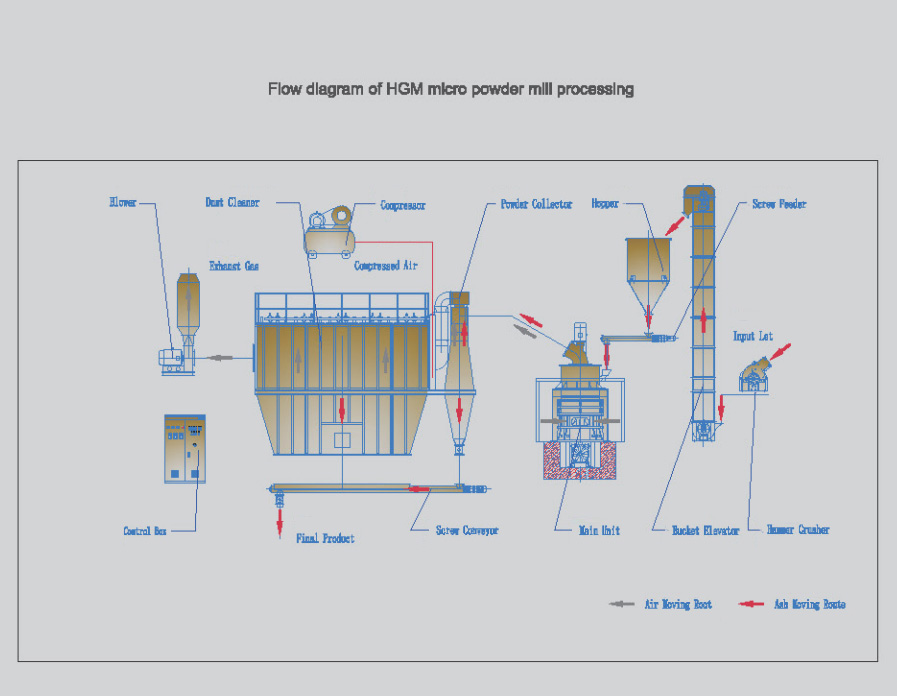

The HGM Micro PowderGrinding Mill includes the main unit, classifier, crusher, elevator, hopper, and feeder. Materials are crushed, sent to the hopper, and evenly fed to the turning plate for grinding

The Micro Powder Grinding Mill operates by driving grinding rollers in ring channels via a motor and reducer. Materials are pushed to the turntable’s edge by centrifugal force, falling into grinding chambers where they are repeatedly pressed, crushed, and ground into fine micro powder.

The high-pressure blower carries crushed materials to the classifier, where unqualified particles are reground and qualified ones enter the cyclone collector. Most powders exit via the discharging valve, while finer powders are collected by the dust cleaner and conveyed for packing. Clean air is emitted through the muffler.

Features

- High Efficiency:

Under the same finished final size and the same motor power,the capacity of the micro powder grinding mill is twice as much as that of jet mills,mixing grinders,and ball mills,with energy consumption decreased by 30%. - Long Lifespan of Spare Parts:

The ring and roller are forged from special materials with high utilization.Under the same grinding material and finished size,the lifespan of spare parts is about one year,which is 2-3 times longer than that of impact mills or turbo mills.Furthermore,the lifespan can reach 2.5 years when grinding calcium carbonate.The lifespan of spare parts varies depending on the hardness of the material. - High Safety and Reliability:

As there are no rolling bearings or screws in the grinding cavity,there are no issues caused by bolt shedding or rapid wear of bearings and sealing components. - High Fineness,Flexible Adjustment:

The final fineness of the grinding materials can be adjusted between 200 mesh and 2500 mesh(74-5 microns). - Environment-friendly:

The application of pulse bag filters and mufflers greatly alleviates dust pollution and noise. - Advanced Intelligent Speed Control Device:

It allows the material to feed into the machine evenly,adjusts the main speed to fit the ground material,and stabilizes the fineness.This increases capacity and efficiency while reducing power consumption.

Parameter

| Main Specification | |||||

| Model | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM1680L |

| Rlng Dlameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number(layer) | 3 | 3 | 4 | 4 | 4 |

| Roller Number(piece) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 |

| Main Shaft Speed(r.p.m) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size(mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| FInlshed Slze(um/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-6 (150-2000) | 100-9 (150-1500) |

| Capacity(th) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 |

| Overall Dimension(LWH, m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 |

| Power Parameter | |||||

| Unit: KW | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM1680L |

| Main Unit | 75 | 2*45 | 132-150 | 185-200 | 315 |

| Classlfler | 18.5 | 18.5-30 | 30-37 | 75 | 132 |

| Blower | 45 | 55 | 75 | 110 | 200-220 |

| Crusher | 18.5 | 18.5 | 18.5 | 45 | 45 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 7.5 |

| Feeder | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Discharging Valve | 2*0.75 | 1.1 | 1.1 | 1.5 | 2*1.5 |

| Air compressor | 11 | 15 | 22 | 37 | 55 |

| LS-POP (VI) Type | ||

| Lower Limit Of Truncation: 0.20 | Fit Remnants: 0.02 | Test Time: 17:47:50 |

| Sample Refractive Index:1:60 | Upper Llmlt OfTruncaton:517.20 | Uirasonlc Tlme:2″ |

| Medlun Refractive Index: 1.33 | Test Date:2010/8/15 | Shad ing Ratio:14.98% |

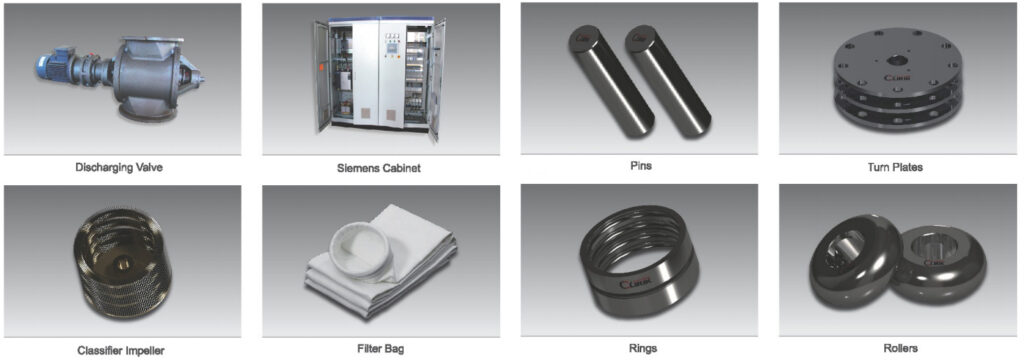

Components and parts