PRODUCT OVERVIEW

Clariant launched the CLUM series ultrafine vertical roller mill, which integrates grinding and grading functions.

The powder fineness reaches 400-3000 mesh, breaking the bottleneck of production capacity. More than 30 production lines have been installed worldwide

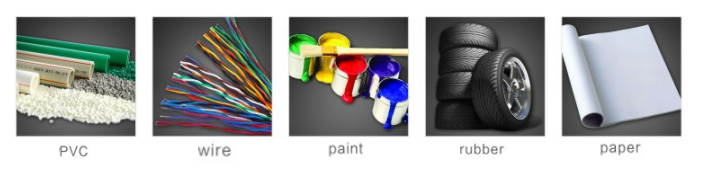

APPLICATION FIELDS

CLUM series ultrafine vertical roller mill is suitable for chemical, metallurgical, non-metallic mining and other industries. It can process non-metallic materials such as calcite, marble, limestone, etc., and provide high-quality fillers for papermaking, plastics, rubber and other industries.

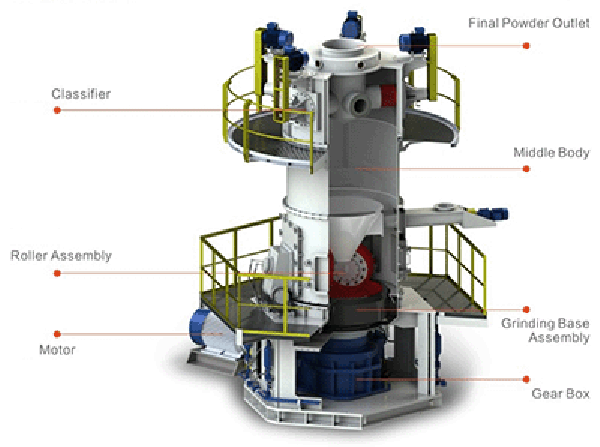

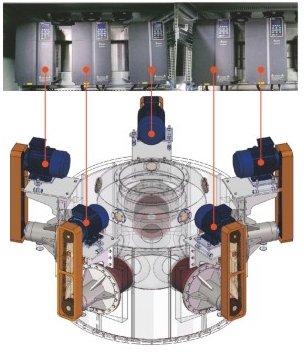

MAIN STRUCTURES

CLUM series ultrafine vertical roller mill is composed of motor, reducer, grinding roller, grinding disc, pressure device, classifier, etc.

The grinding roller rotates passively by friction, the grinding disc is driven by the reducer, the pressure device adjusts the gap between the grinding roller and the grinding disc, and the classifier uses centrifugal force to separate fine powder, realizing efficient and energy-saving powder selection function.

WORKING PRINGIPLE

Grinding process

The grinding disc is driven by a motor to rotate, and the material moves from the center to the edge. After being crushed and ground by the grinding roller, the fine powder is taken away by the air flow.

When the material passes through the separator, the coarse particles return to the grinding disc and are crushed again, while the fine particles are discharged with the air flow and collected into finished powder by the powder collector.

Final product quality guarantee

The coarse granular and impurities will fall into the lower grinding chamber, and be discharged

out by the scraping plate.

High-precision multi-rotor classifier adopts frequency control, adjustable rotor speed,

produces various particle size.

Adjusting the hydraulic system pressure to change the roller pressure, fit for materials with

different hardness.

Electronic caging device makes sure the safety gap between roller and plate, effectively avoide

the heavy vibration due to lack feeding.

TECHNICAL ADVANTAGE

The grinding roller and liner are made of wear-resistant alloy, which has a long

service life and requires less maintenance. The unique grinding curve design has a stable material bed,

small vibration and high efficiency. The production capacity is 20% higher than that of similar vertical mills and 40% more energy-saving than ball mills.

TECHNICAL PARAMETERS

M a i n c o n f i g u r a t i o n a n d p r o d u c t i o

| 型号Model 项目Item | CLUM1425 | CLUM1632 | CLUM1736 |

| 转盘直径(mm) Plate Diameters(mm) | 1400 | 1600 | 1700 |

| 磨轮数量(个) Number of rollers(pieces) | 3 | 3 | 3 |

| 分级叶轮数量(个) Number of classifier(pieces) | 6 | 6 | 8 |

| 分级机功率(Kw) Power of classifier(Kw) | 6X15 | 6X22 | 8X22 |

| 主机功率(Kw) Main unit power(Kw) | 220-250 | 315-355 | 355-410 |

| 风机功率(Kw) Blower power(Kw) | 180-200 | 250-280 | 325-355 |

| 入磨物料粒度(mm) Feed size(mm) | <10mm | <10mm | <10mm |

| 入磨物料水分 Moisture of feeding material | <3% | <3% | <3% |

| 小于2μm=30%产量(t/h) Less than2μm=30%output(t/h) | 9-12 | 12-16 | 14-18 |

| 小于2μm=45%产量(t/h) Less than2μm=45%output(t/h) | 5.5-7.5 | 7-9 | 10-12 |

| 小于2μm=60%产量(t/h) Less than2μm=60%output(t/h) | 3-4 | / | / |

Particle size distribution:measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments